Skilled professionals with decades of combined experience

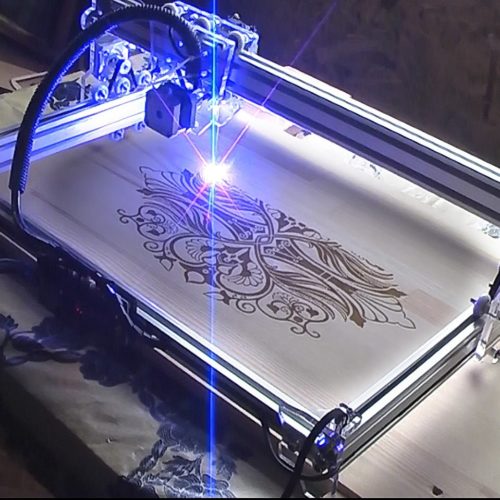

Hi-tech laser cutting equipment for precision results

Accuracy and clean finishes guaranteed every time

Delivering excellent results to Perth businesses and hobbyists

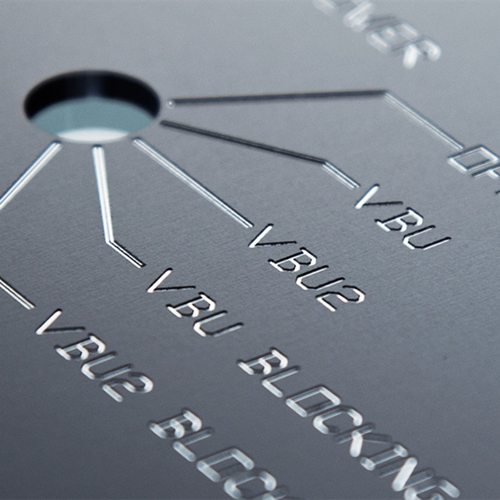

Metal fabrication is the process of shaping raw metal into useful products or structures through cutting, bending, welding, and assembling. It combines skill, precision, and technology to transform steel, aluminium, and other metals into custom solutions for industries, homes, and commercial projects.

From kitchen benchtops and structural frames to complex machinery parts, metal fabrication plays a key role in everyday life. Our expertise lies in turning design ideas into durable, functional results that meet exact requirements. With 20 years of hands-on experience, TRUCUT provide reliable, high-quality fabrication services that showcase both expertise and technical knowledge.

We work with the highest quality metals to meet your project’s specifications and requirements.

0.5mm - 25mm

Versatile and cost-effective material perfect for structural applications, general fabrication, and industrial

components.

0.5mm - 20mm

Corrosion-resistant material ideal for food service, medical equipment, and applications requiring hygiene and durability.

0.8mm - 15mm

Lightweight yet strong material offering excellent corrosion resistance and thermal conductivity for diverse applications.

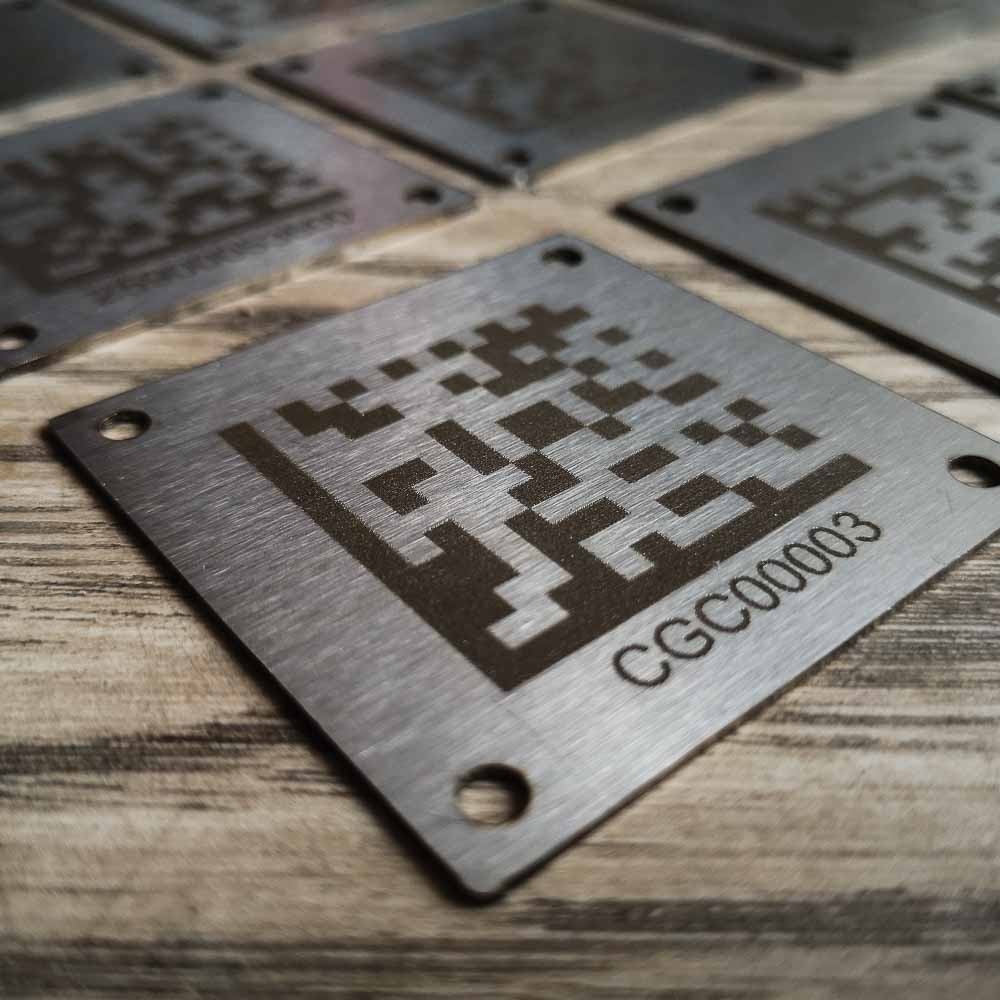

Yes, a laser engraver can etch metal. Etching involves using a laser beam to create a shallow, textured surface on the metal. This technique is often used to create designs or patterns that are slightly recessed into the material.

Removing laser etching on metal is generally difficult, if not impossible. The etching process permanently alters the surface of the metal, making it difficult to restore to its original state.

The time it takes to mark metal with a laser depends on several factors, including the size and complexity of the design, the thickness of the metal, and the power of the laser. However, laser marking is generally a quick and efficient process, often taking only a few minutes for smaller designs.

While etching and engraving are both used to create designs on metal surfaces, there are some key differences:

Laser marking and laser etching are similar processes, but they differ in the depth of the mark

created:

Solutions Available

Material Thickness

Project Sizes