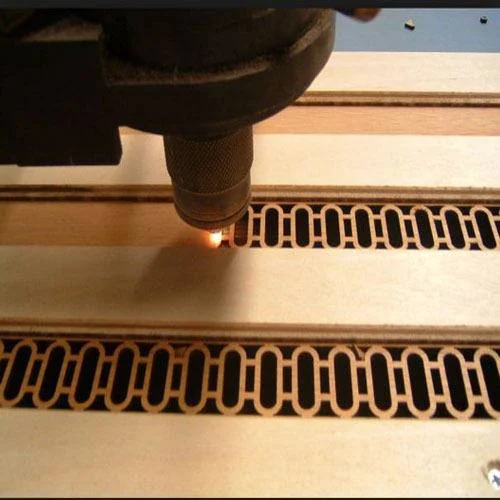

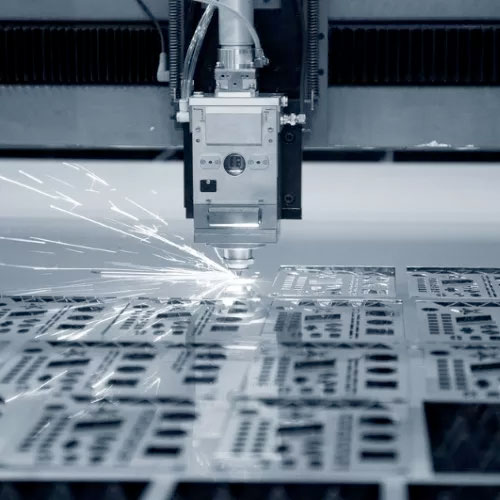

Finishing in laser cutting is the process of perfecting and refining the edges and surfaces of your cut materials. Once the laser cutting is complete, the finishing process ensures the final product is smooth, polished, and ready for use.

After your metal, wood, or plastic is cut, we apply treatments to clean up the edges, remove any burrs, and create a sleek, professional finish. We may also apply coatings or polishing techniques to protect the material and give it a flawless look. Finishing makes a huge difference, giving your project that clean, polished look it needs to stand out.

Our finishing services are versatile and can be applied to a wide range of projects. Whether

you’re creating something for your business or personal use, here are just a few ways people use

our finishing expertise:

Smooth, polished parts that are ready for assembly or packaging.

Perfect edges and finishes for wood and metal furniture.

Clean, sleek finishes for commercial signs or display pieces.

Make sure building elements like panels, fixtures, or brackets have the refined look they need.

Bring creative projects to life with precision finishes for metal, wood, or plastic pieces.

At TRUCUT Perth, we know that the little things matter. A proper finish isn’t just about making

things look good—it also adds value in many ways:

Finishing can turn a simple cut into a high-quality, ready-to-use product. That’s why it’s

important to get it done right.

Protective finishes help resist corrosion, rust, and wear over time.

A smooth, polished surface gives your product or project a professional appearance.

Finishing ensures that sharp edges or rough surfaces don’t interfere with how the product works.

Want to know exactly how we transform your laser-cut parts into finished products? Here’s a

quick look at our process:

Depending on your project, we’ll polish, coat, or apply other finishes to create a smooth surface.

Every piece is inspected to ensure it meets our quality standards before delivery.

No two projects are the same, and neither are our finishing services. We offer a range of finishing options to match your exact requirements:

Get a shiny, mirror-like finish on metal or other materials.

Smooth out rough or sharp edges for a clean, safe finish.

Apply protective layers to shield your materials from damage, moisture, or corrosion.

Want something a bit more unique? We can create matte, brushed, or custom textures to give your project character.

Without the proper finishing, even the most well-cut materials can fall short of professional standards. Here’s why finishing is so important:

Finishes protect your materials, ensuring they last longer and stay in great shape.

Say goodbye to rough, sharp edges and hello to smooth, polished results.

A polished finish enhances the appearance of your project, making it stand out for all the right reasons.

You get top-quality finishing at prices that fit your budget.

We use the latest tools and methods to ensure a perfect finish, no matter the material or design.

We work with you every step of the way to ensure you’re happy with the final product.

Every project is inspected closely to make sure the finish is smooth, precise, and high quality.

Get your projects finished and delivered on time. We work efficiently without cutting corners on quality.

We can handle all kinds of materials—metal, wood, plastic—and offer different finishing options to match your needs.

Our finishes are not just about looks; they protect your materials from wear, corrosion, and damage.

We’ve built a strong reputation in Perth for delivering reliable and high-quality finishing services.

We ensure every project gets the perfect finish. Whether you need polished edges, smooth surfaces, or protective coatings, we’ve got the tools and expertise to make it happen.

Absolutely! Every project is unique, and we offer customized finishing services to match your specific needs.

The time depends on the size and complexity of your project, but we always aim for fast turnaround times without compromising quality.

We can finish a wide range of materials, including metals, plastics, and wood. Just let us know your project details, and we’ll handle the rest.

Yes! We can apply various protective coatings or finishes to ensure your materials stay looking great and are protected from wear and tear.

Yes, we can apply finishes to a wide variety of materials such as metals, wood, and plastics.

We’ll guide you through the options and recommend the best finish based on your material and project needs.